Research fields DCM

Electrically conductive composites and nanocomposites

Most of polymers exhibit very low thermal and electrical conductivity. However, many industrial applications, heat exchangers, printed circuit boards, temperature-dependent resistors and sensors, electroconductive materials for electromagnetic shielding, require an increase in thermal and electrical conductivity of used materials. For obtaining materials with suitable electrical properties in addition to conventional electroconductive fillers such as carbon black and graphite, more efficient electrically conductive fillers, especially carbon nanotubes and graphene are long-term studied in the DCM.

Sensors for determination of deformation or for the presence of chemical gases, based on conductive nanocomposites, have been prepared using various polymeric matrices (PVDF, SBR, SEBS-MAPEG) with multiwall carbon nanotubes (MWCNT) and carbon black. Deformation of conductive samples was studied by in-situ electrical conductivity measurements during tensile loading. Prepared nanocomposites based on the PVDF matrix can be used as sensors to indicate dimensional change or deformation.

Electrically conductive polymer composites were also tested as gas sensors. Responses of these materials were compared in the presence of a few different organic gases such as toluene, chloroform, THF, and the others. Since all prepared SBR composites were either crosslinked or amphiphilic, they are not subject to degradation due to organic solvents presence and therefore they can be used repeatedly as protective alarms or simple sensors for indication of the presence of various organic gases and for the monitoring of industrial premises.

Actuators were studied in DCM within the 7RP project NOMS. The research was focused on the preparation of nanocomposites with an elastomeric matrix (styrene-isoprene-styrene copolymer or ethylene-vinyl acetate, etc.) containing MWCNT. MWCNTs were non-covalently modified using various surfactants to achieve good dispersion of the nanoparticle in the matrix. We have also developed several original methods to study the actuation of the prepared nanocomposites. Depending on preparation method, after LED irradiation, nanocomposites showed a bimodal and fully reversible response of samples tested in the form of strips.

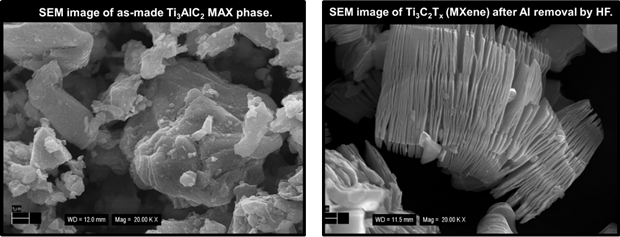

Multifunctional composites with excellent electrical and mechanical properties using new 2D type of nanoparticles – MXenes as fillers in polymeric matrices are prepared within the Horizon NANO2DAY project. The development of new composites is aimed to the use of these materials for flexible electronics and advanced construction components, for wind power plants, components for electromagnetic shielding, etc.

Considerable attention is paid to conducting polymers and carbon nanoparticles for their remarkable physical and chemical properties. Polypyrrole (PPy), polythiophene and polyaniline are mainly studied in DCM. Our research is also devoted to combination of conducting polymers with other polymers, organic or inorganic substrates, with the aim to create a new kind of materials for applications in new types of devices. The colloidal dispersion of polypyrrole-silver nanoparticles prepared by a one-step oxidation of pyrrole with silver nitrate in poly (N-vinylpyrrolidone) or poly (vinyl alcohol) solution was tested as a conductive ink.

Recently, stable hybrid electrodes based on PPy and carbon nanoparticles (carbon nanotubes or graphene) have been prepared and tested for solar cell applications. Thin PPy/carbon nanoparticles hybrid films were prepared by chemical or electrochemical polymerization and tested as replacements for standard Pt counter electrodes in solar cells. PPy/MWCNT samples prepared by electrochemical polymerization achieved the best results when anionic surfactant (sodium dodecylbenzene sulfonate) was present during polymerization. Broad international cooperation has been developed for the preparation of stable solar cells based on perovskite structures, where also developed hybrid composite electrodes based on conducting polymer and carbon nanoparticles can be used.

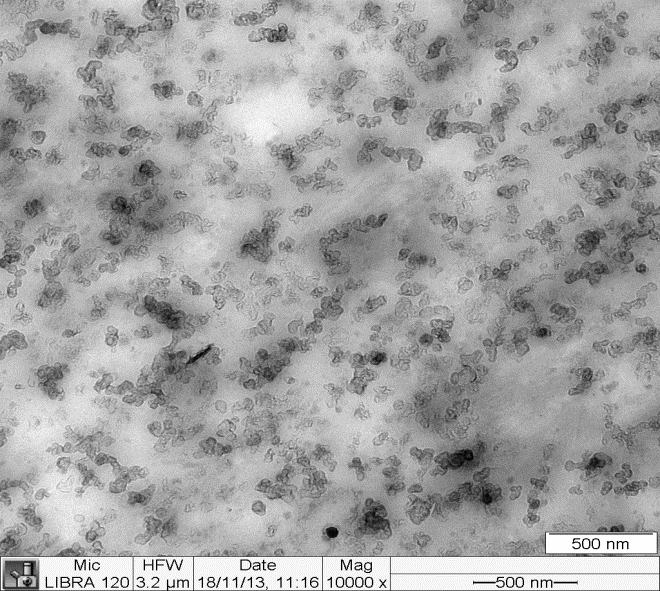

Graphene-oxide multifunctional nanoplatform (GO-MFN) for the detection of tumor cells has been developed in DCM recently. In a first step, 300 to 500 nm GO nanolayers were prepared and functionalized with magnetic nanoparticles and a monoclonal antibody (MAb) specific for CA IX marker. Subsequently, GO platforms were characterized in terms of oxidation, nanoparticle size and exfoliation, using various physical and chemical methods. Magnetic nanoparticles (MNps) were prepared by the chemical precipitation method and their surface-was modified by D, L-lysine (DLL). CA IX-specific antibody was attached via an amide bond to a modified magnetic nanoparticle that was conjugated to the GO platform again via an amide bond. After performing toxicological tests on the B16-F0 cell line, no effect of the cytotoxicity of the multifunctional GO platforms was found. The immunofluorescence assay indirectly confirmed binding between graphene oxide and monoclonal antibody conjugated magnetic nanoparticles. The selectivity of GO-MNps-MAb platforms to target tumor cells has been demonstrated. The project results have provided promising evidence of tumor cell targeting with a wide potential for visualization and future tumor treatment.

DCM is also working on the development of innovative 2-dimensional MoS2 multifunctional nanoplatforms for the detection and treatment of tumor cells.

Biodegradable and compostable plastics

Concerning biodegradable plastics materials, extensive experience and significant results were collected in the Department of Composite Materials. Current effort is aimed to obtaining new materials with potential for high-volume applications especially for packaging. Among the most important recent results, the development of biodegradable blend polylactic acid / polyhydroxybutyrate should be mentioned possessing substantially higher toughness compared to other materials of similar composition described in scientific and patent literature. The blend was developed in cooperation with Faculty of Chemical and Food Technology of Slovak Technical University and patents were awarded in EU and other countries (such as China, Russia, Korea, Singapore, Japan and few others); the pilot production of pellets is starting in Slovakia in 2020.

The research on biodegradable plastics is aimed also to development of materials applicable as mulching films in agriculture degradable in compost. In cooperation with Slovak Agriculture University in Nitra the developed materials were applied as foils at farming of paprika; positive effect was observed for both size of the pieces and overall yield. Additional characterization methods were introduced, enabling detailed kinetics measurements and degradation degree in various environments including compost.

Recently the investigation of biodegradable plastics is targeted also at basic research regarding preparation of thermoplastic starch (TPS) and its modification. The TPS-based materials are optimized for applications as additives to biodegradable plastics resulting in more competitive economic parameters towards commodity plastics on one hand, but also applicable as matrix polymer for preparation of products with higher added value on the other hand. Another topic related to TPS-containing BDPs consists in modification by addition of nanoparticles and other fillers aimed to preparation of special materials for advanced applications.

Antibacterial materials

Materials based on quantum dots

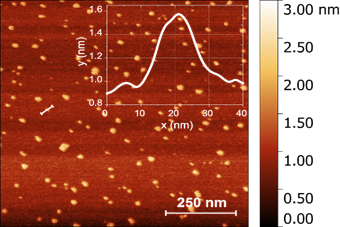

Recently, a class of carbon nanoparticles has been synthesized, characterized by significantly higher chemical inertness and biocompatibility than conventional semiconductor quantum dots, namely carbon quantum dots (CQD). CQDs are an effective source of singlet oxygen, which is produced after irradiation with light and disrupts bacterial membranes in a very short time. Properties of prepared CQDs, such as photoluminescence, ability to produce singlet oxygen and other physicochemical properties are studied in DCM. In the department, we developed hydrophobic CQDs that do not react with fluids in the human body, are non-toxic to living organisms and are characterized by biological activity controlled by light. These 5 – 15 nm CQDs were subsequently incorporated into polymers used in medicine or for the treatment of textiles, windows, walls, and others. Thus, polymer composites with controlled antibacterial activity on durable polymers have been obtained, which can be successfully used for floor coverings and wall cladding in hospitals where the antibacterial effect will be controlled by the number of LEDs during working time.

Preparation of antibacterial polymer surfaces by low-temperature plasma. Adhesion of bacteria to polymer surfaces is mediated by physicochemical interactions between the bacterial strain and the polymer surface and depends on the bacterial strain type, chemical polymer composition, roughness, wettability, surface charge and density. Surface of low density polyethylene (LDPE) was modified by microwave plasma enabling functionalization with N-allylmethylamine accompanied by brush formation. Three fluoroquinolones, enroflaxocin, lomefloxacin and sparfloxacin were immobilized on the polymer surface, forming an active antibacterial layer active against nosocomial infections. The antibacterial effect of immobilized enroflaxocin specimens was evaluated as the best independent of pH. The sparfloxacin sample showed the lowest antibacterial effect against E. coli, but even in this case the effect was approximately 20 times higher compared to the unmodified LDPE reference surface.

Targeted research

Materials for 3D printing

3D printing is an additive process in which a 3D object is created according to digital template. This method is currently most often used for the production of functional components, when the molten thermoplastic material is gradually deposited layer by layer to form a 3-dimensional object. The advantage of the technology is the production of multicolored prints as the printing device can contain more nozzles. In DCM, various polymer composites are prepared with carbon-based or natural mineral fillers, which subsequently produce the filaments for printing. Newly-developed composite filaments have higher strength, lower density and are cheaper. The filler has lubricating effects, reducing abrasive properties, improving rheological properties and giving the filaments /3D objects a fine texture. Due to the high thermal conductivity, it is not necessary to change the temperature parameters of the printing.

New types of nanofibers prepared by electrospinning

The electrospinning method was used for the preparation of nanofibers in the form of nonwoven textiles based on ethylene vinyl acetate copolymer and polylactic acid, as well as polyvinylpyrrolidone (PVP) containing gum tragacanth polysaccharide and polycaprolactone polypyrrole (PCL/PPy) composites. An original procedure was used to prepare conductive PCL/PPy fibers. Electrically conductive nonwoven fabrics were prepared with different ratios of PCL to pyrrole monomer. The prepared nanofibers were homogeneously coated with polypyrrole and samples containing at least 40% by weight of the conductive component had an electrical conductivity higher than 1 S/cm. Due to the fact that their biocompatibility has been proven, this material can be used in bioelectronics application.

Advanced and unique equipment for investigation of multiphase materials with polymeric matrices

X-ray photoelectron spectroscopy (XPS) is an appropriate method for characterization of surfaces of various materials. XPS is used for the analysis of solid surfaces, thin films and powdery materials, as well as for mapping the surface contamination and corrosion, characterization of surface defects, oxidized layers, and determination of surface modification degree. XPS analysis provides chemical composition of surfaces, chemical characterization of modified polymeric materials, composition of depth profiles of multilayer materials and analysis of interphases.

Using nanoindenter various quasistatic indentation analyses can be performed applying automatized measurements at very low stress. The equipment is used for characterization of microhardness of thin layers. The principle consists in a measurement of depth of tip penetration under application and release of stress. Important outcome from nanoindenter measurements is a possibility of Young’s modulus calculation of thin layers.

Wetting of the surfaces with various liquids can be determined by contact angle analysis. The value of contact angle indicates hydrophilicity / hydrophobicity of the surface and enables to calculate the free surface energy including its polar and dispersive component.

Broadband dielectric spectrometer represents a highly efficient system for the frequency range from 3 μHz to 20 MHz (12.5 decade), based on modular measurement system Alpha-A for measurements of dielectrics, electrical conductivity, electrochemical and impedation spectroscopy with several testing interfaces. Dynamical-mechanical analysis (DMTA) is a complementary method, which provides quantitative data regarding glass transition temperature, the polymer blends structure, especially concerning the miscibility of the components, and dynamics of amorphous phase of noncrystalline or semicrystalline polymers.

In DCM, other techniques are available for characterization of either physical or chemical properties of materials such as dynamometer Instron, universal equipment for determination of mechanical properties of vast range of materials or rheometer for measurement of rheological properties of polymeric materials. Detailed description of the equipment available at DCM can be found at polymer.sav.sk/OKM-Equipments

contacts

contacts